The difficult path to climate neutrality

Steel

Steel Cement

Cement Paper

Paper Plastics

Plastics Aluminium

Aluminium Glass

Glass Aviation

Aviation Shipping

Shipping Agriculture

AgriculturePlastics

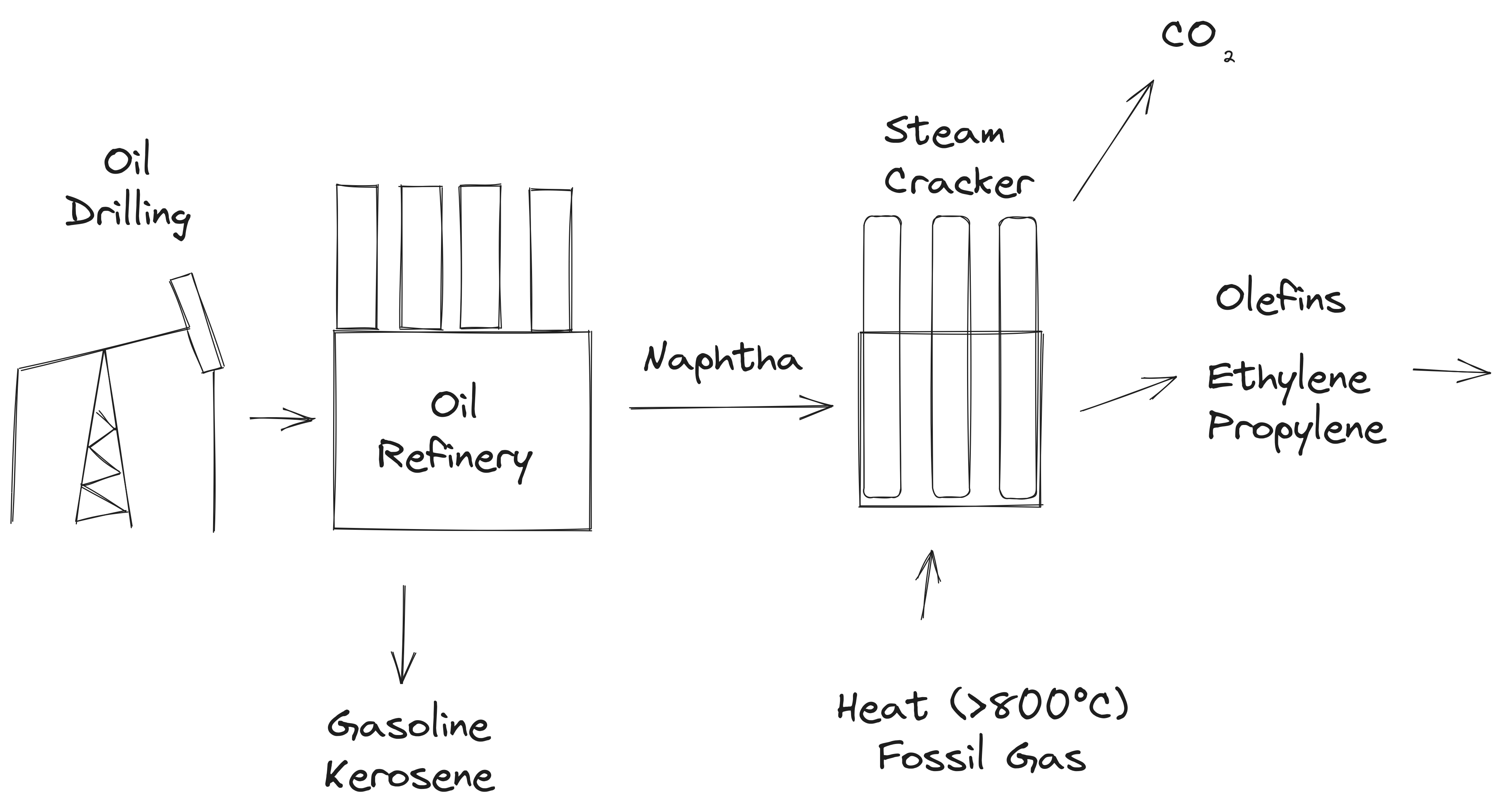

Steam Cracker

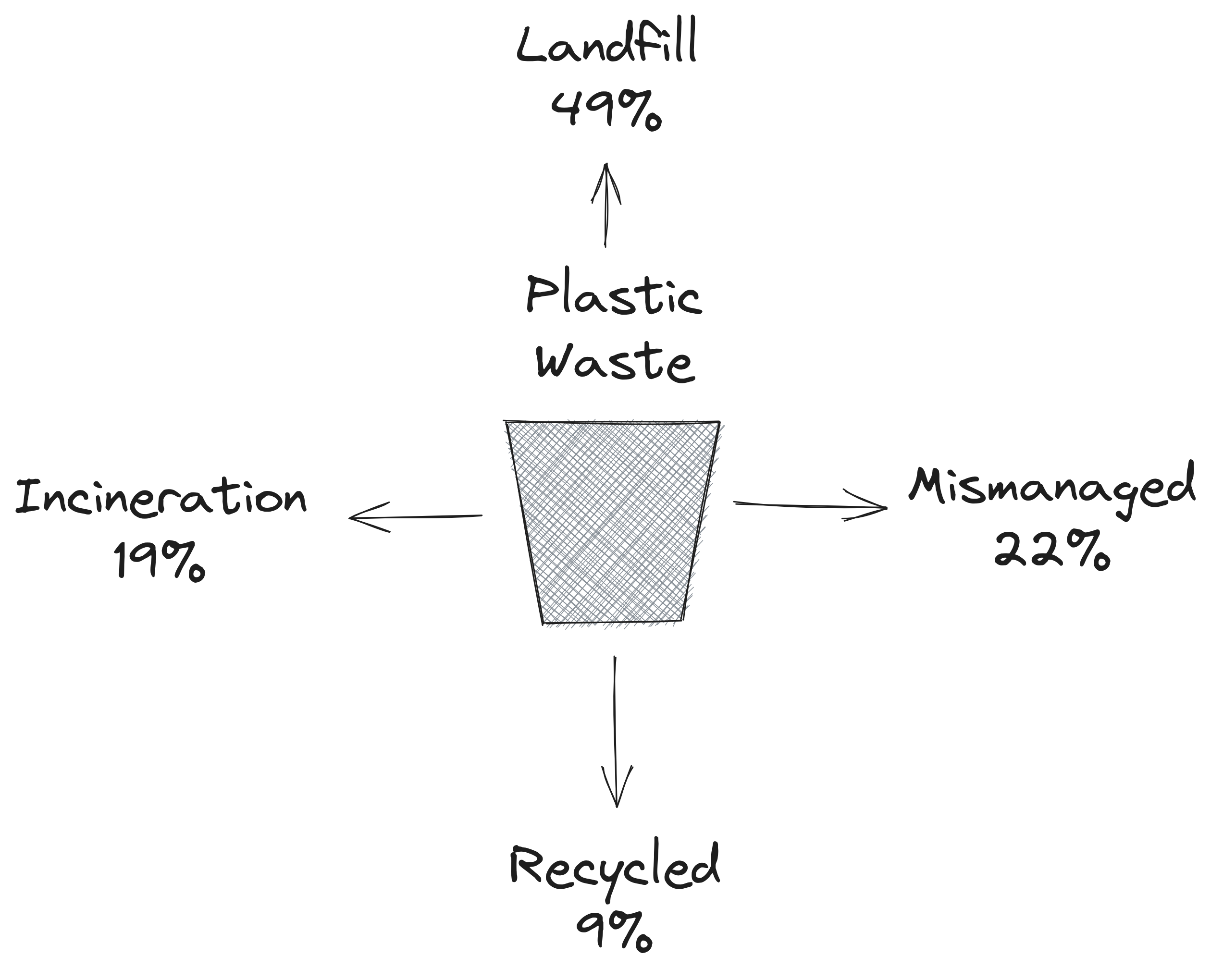

Mismanaged

Plastics can degrade to Methane and Ethylene

Landfills are a major source of Methane emissions

Waste Incinerators

Highest CO₂ emissions

Recycling: Emissions from energy use, still best option

How should we think about plastic's end-of-life emissions?

Plastics are fossil fuels

If we want to clean up the production of plastics and chemicals, we need to consider both:

- Fossil fuel energy

- Fossil fuel feedstock

Electrification

BASF is currently building the world's first electric Steam Cracker furnace in Ludwigshafen

Around 1,8 percent of BASF's Steam Cracker capacity in Ludwigshafen

BASF Furnace: 6 Megawatts

If scaled up to the capacity of BASF Ludwigshafen: 350 Megawatts

Electric Steam Cracking

It is in the early stages, but it appears doable

Replacing fossil fuel feedstock

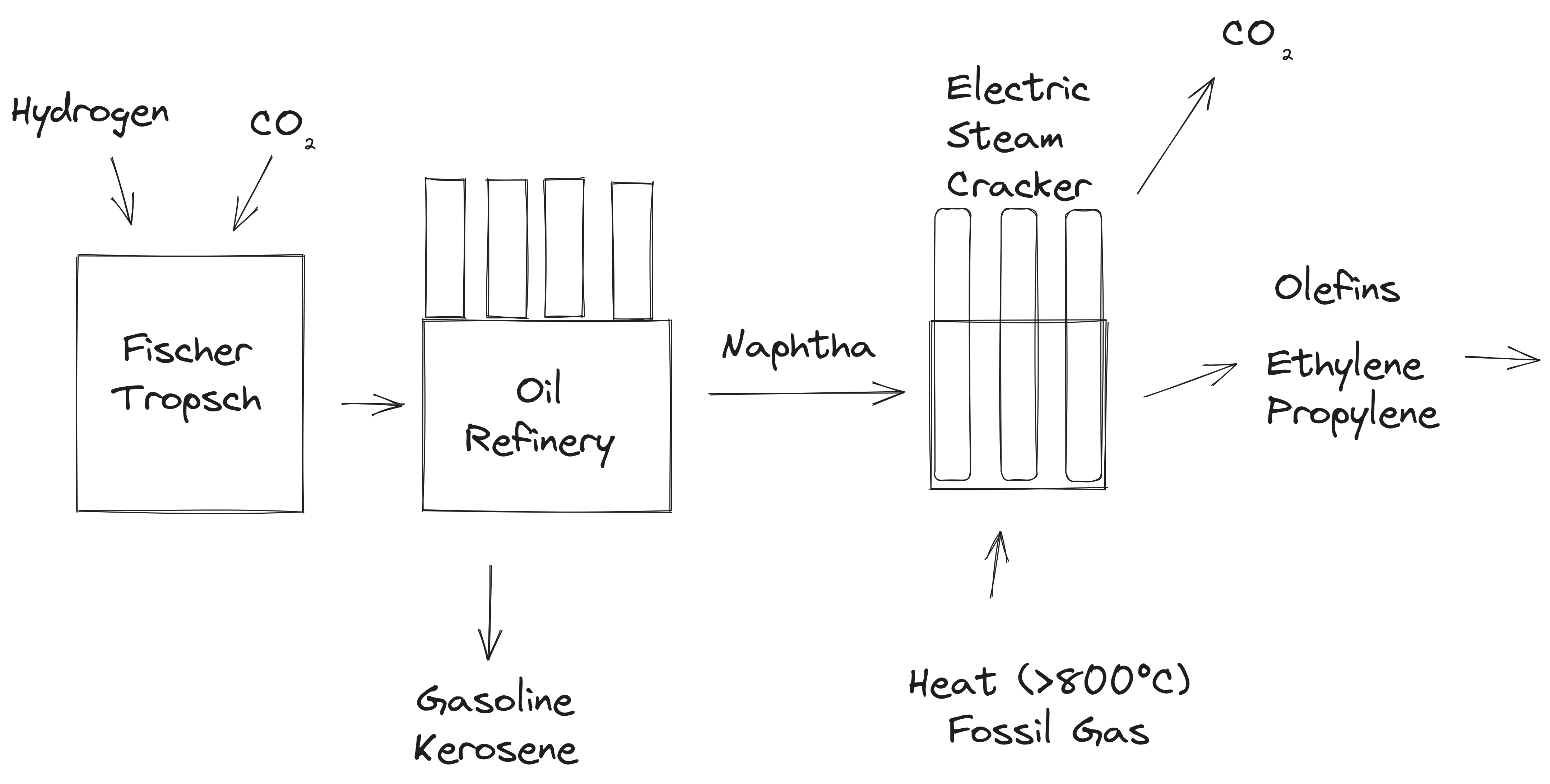

Power-to-X

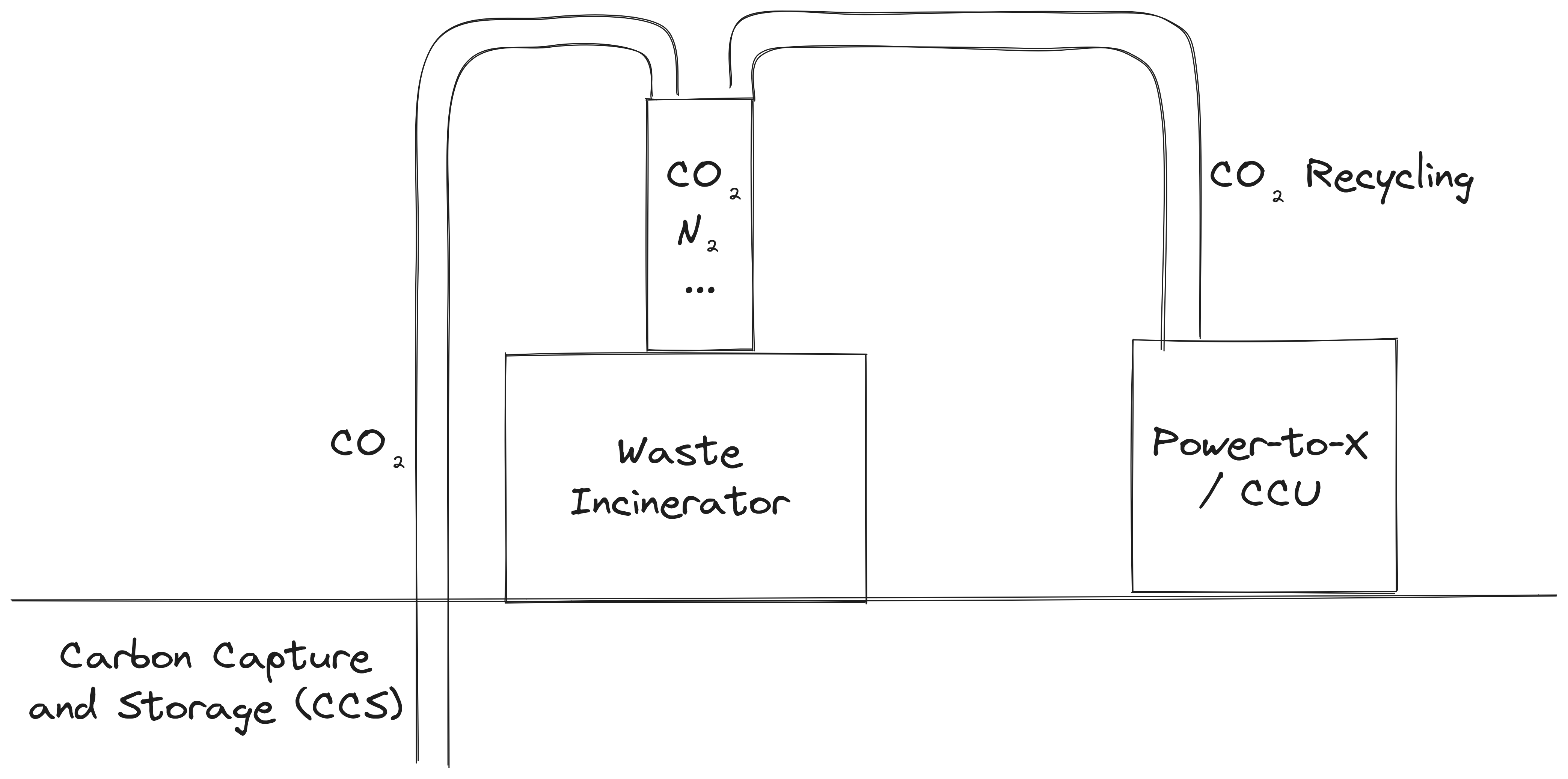

Carbon Capture and Utilization

Where does the CO₂ come from?

It requires a lot of energy

- Kätelhön et al, PNAS, 2019: 18-32 PWh (World today: 22 PWh)

- Germany, VCI 2019: 685 TWh, VCI 2022: 464/508/325 TWh (Germany today: 500 TWh)

Can we make this more efficient, and are there alternatives?

Not all Power-to-X technologies are the same

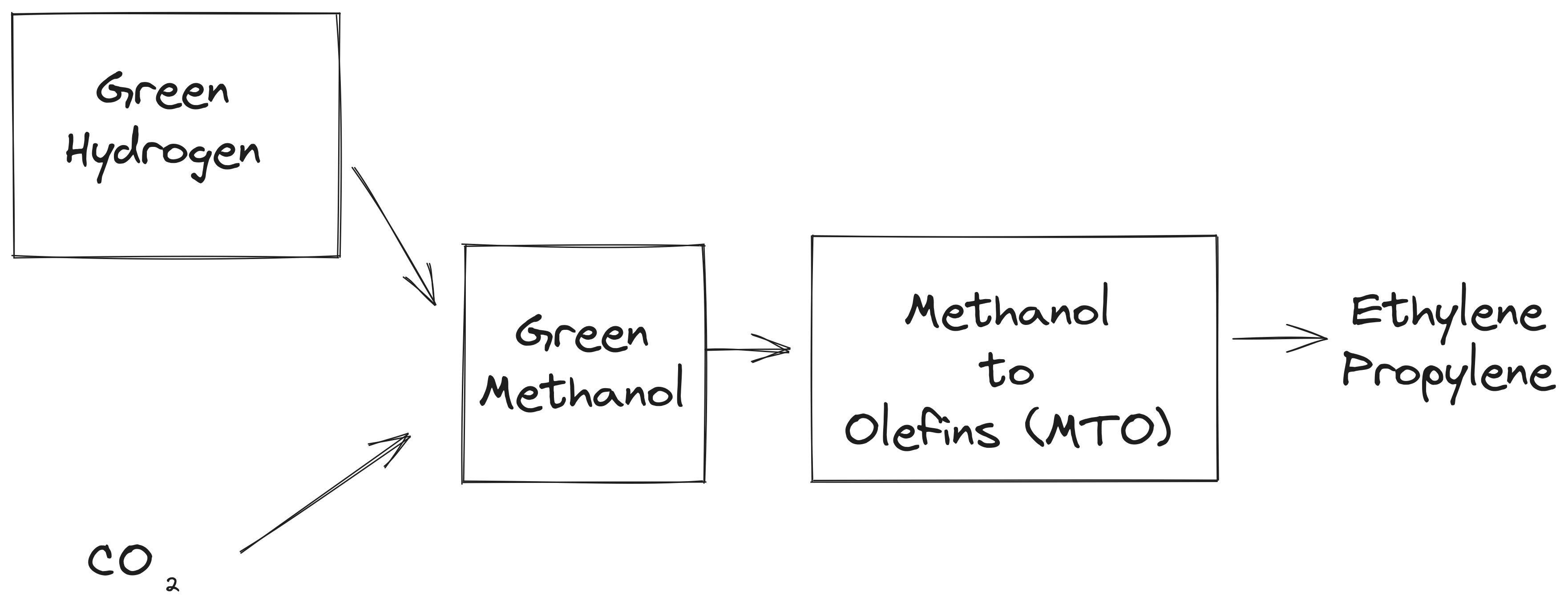

Green Methanol

Sailboat CO₂ to Green Methanol project

Collaboration between Jiangsu Sailboat (China) and Carbon Recycling International (Iceland) at China's largest Methanol to Olefins facility

E-Naphtha and electric Steam Crackers

or

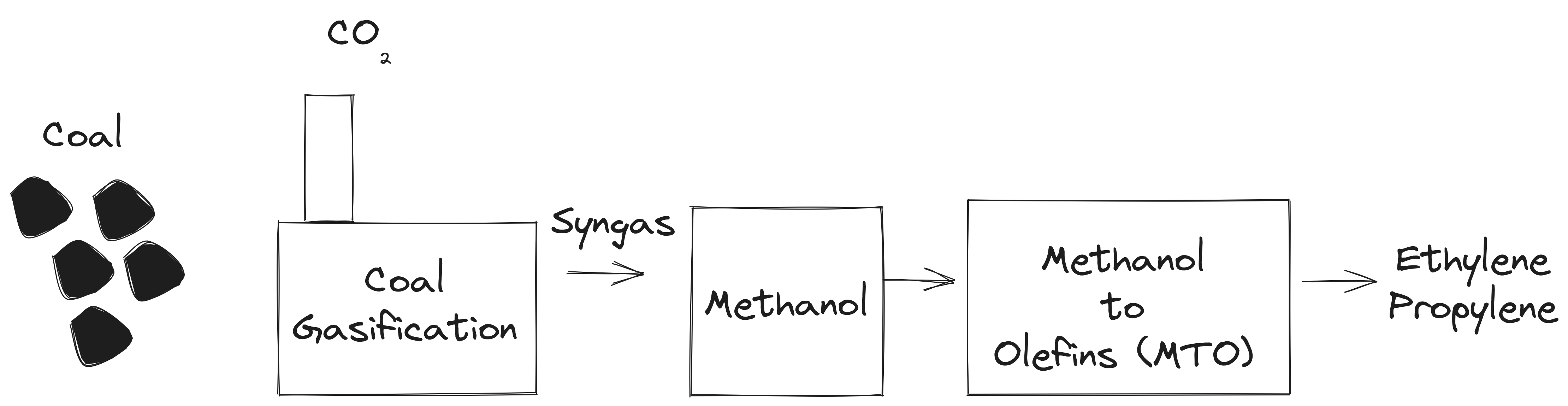

Green Methanol and Methanol-to-Olefins

Methanol-to-Olefins is more efficient and requires less energy

Other options

Use less

But beware of unintended consequences

Biomass

Possible, but probably limited availability

Recycling

Plastic recycling rate is 9% worldwide, but it differs widely

Chemical Recycling

Gasification

Pyrolysis

There will probably always be some non-recyclable waste

CCS/CCU for Waste Incinerators

- Oslo Waste Incinerator with CCS, currently on hold

- Methanol from Waste Incinerator CO₂ in Zella-Mehlis, Germany

Summary plastics

- We can make the chemicals needed for plastics from CO₂ and hydrogen, but it requires enormous amounts of clean energy

- Methanol-to-Olefine technology is probably more efficient than using existing Steam Crackers

- Using less plastics, biomass, more recycling, and new recycling technologies can help

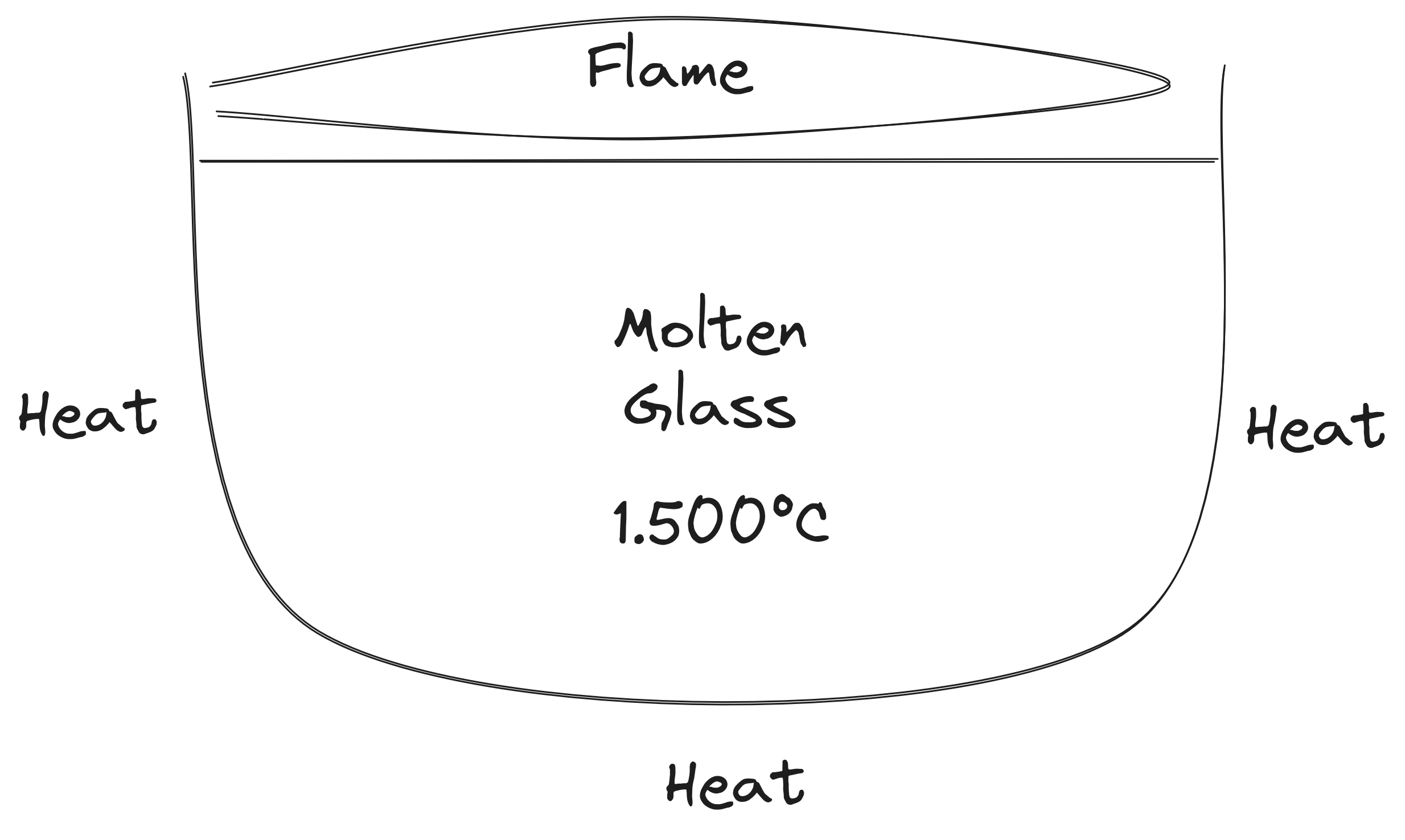

Glass

Can we run glass furnaces on electricity alone?

It's difficult

In 2008 the US company Cameron Glass built a large electric furnace for wine bottles

The furnace was unable to heat the glass evenly, it caused a major accident

Cameron Glass filed for bankruptcy in 2009

Can glass furnaces use mostly electricity and some gas?

Hybrid furnace projects

Next-Gen furnace, Ardagh, Germany

Volta Project, AGC, Czechia

Fossil gas could eventually be replaced by green hydrogen

There is another problem

What is glass made of?

Silica (Silicium Oxide, SiO₂)

Limestone (Calcium Carbonate, CaCO₃)

Soda (Sodium Carbonate, Na₂CO₃)

CaCO₃ → CaO + CO₂

Na₂CO₃ → Na₂O + CO₂

The mineral inputs contain carbon and cause emissions

Recycling can reduce these

Carbon Capture and Storage?

Summary

- Fully electric furnaces are difficult to build

- Mostly electric hybrid furnaces with green hydrogen could decarbonize the energy

- No solution for emissions from minerals (carbonates)

Conclusions

Almost every industry needs to change its processes in major ways to avoid greenhouse gas emissions

Public domain or CC0 pictures used:

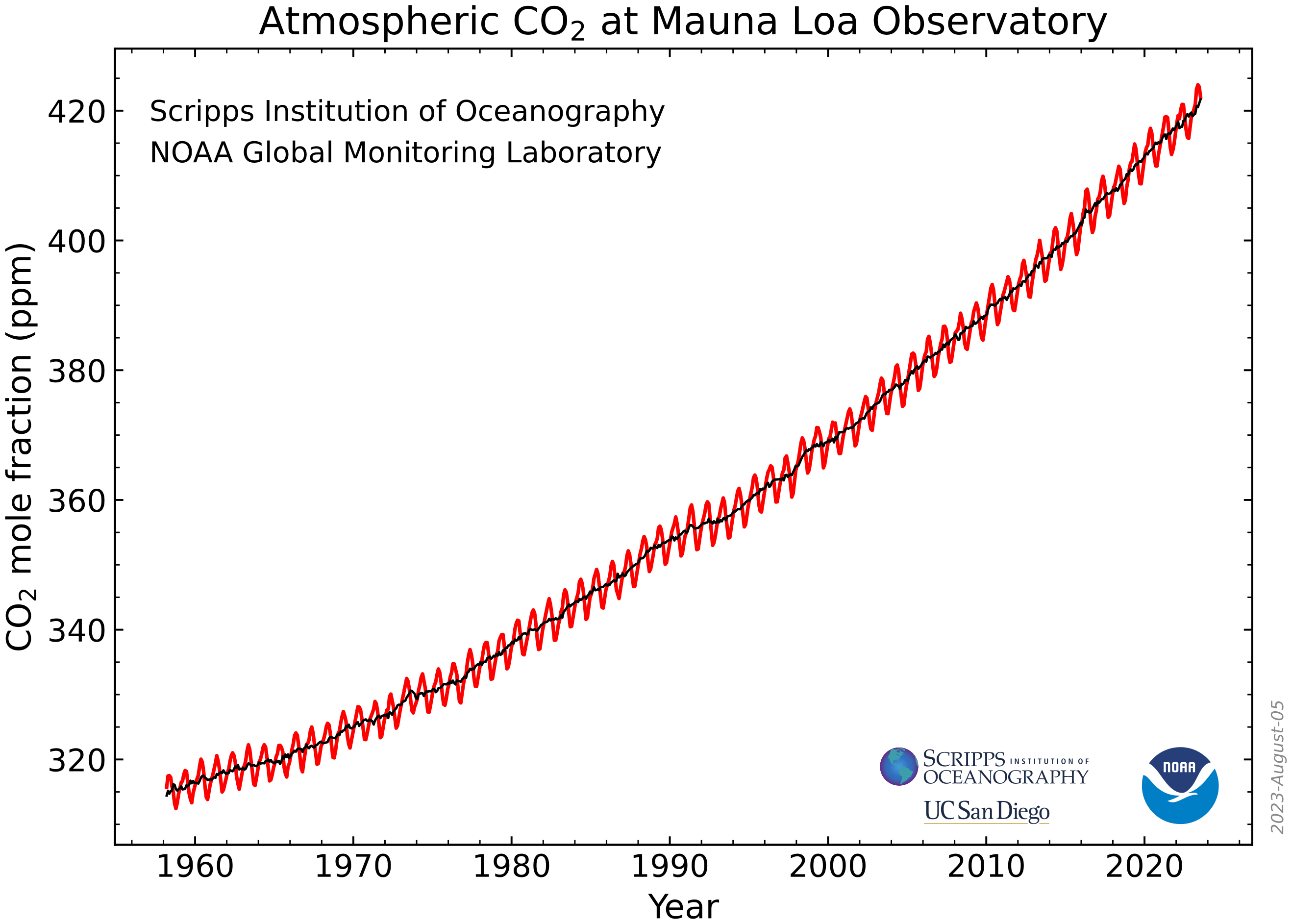

CO2 graph

Concrete

Aluminium

Glass bottles

Airplane

Container ship

Cow

Steam Cracker

Landfill

Waste Incinerator

Soda

All other photos from my own collection. Illustrations created with Excalidraw.